Manufacturing and processing experience

Square meter factory building

mechanical engineer

machining equipment

Our company was founded in 1998 and has been engaged in the processing and manufacturing of chemical machinery since its establishment. In 2006, our company was transformed into a limited liability company.

Our company's main products include: stainless steel, carbon steel non-standard pressure vessels, atmospheric pressure vessels; Extraction, evaporation, concentration and drying equipment; Steel lined fluoroplastic series.

MORE

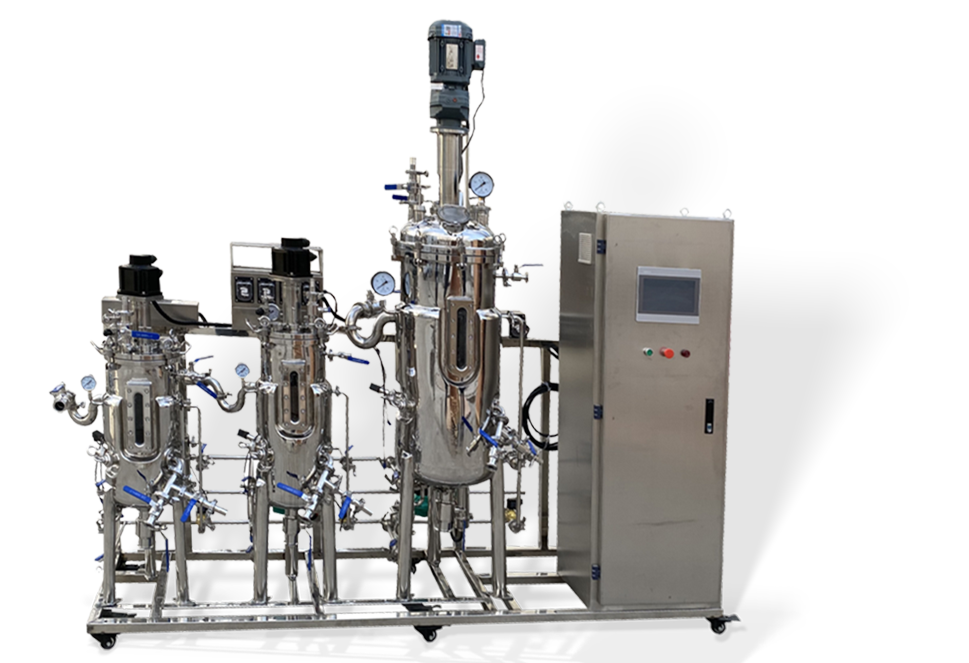

The reaction kettle is composed of a pot body, pot cover, stirrer, electric heating oil clamp pipe, support and transmission device, shaft seal device, oil overflow tank, etc., and is equipped with an electric heating rod, temperature and pressure gauge.

Our company can design and manufacture various forms of shell and tube heat exchangers, with a heat transfer area of 1-1000 square meters. The materials include carbon steel, stainless steel, titanium and their composite materials, and can also be customized according to customer requirements.

Centrifugal scraper film evaporator is a high-efficiency evaporation and distillation equipment that uses high-speed rotation to distribute liquid into uniform film for evaporation or distillation. It can also carry out Unit operation such as deodorization, defoaming reaction, heating and cooling.

See more

This machine has a novel design, simple internal structure, easy cleaning, complete discharge of materials, simple operation, closed drying, no leakage of the product, green and environmentally friendly, suitable for drying strongly irritating and toxic materials.

It is divided into different equipment such as pressure vessels, heat exchangers, fermentation tanks, reaction kettles, etc

The product has excellent chemical stability, temperature resistance, corrosion resistance, and excellent mechanical structure

Extensive use of industrial engineering computer-aided design and process simulation systems to optimize the effectiveness of the entire production process

Customers can provide samples, drawings, sizes, shapes, and other customized designs according to user requirements

There are 16 lifting equipment for manufacturing, which can lift 32 tons. 5 rolling machines, with a rolling thickness of up to 30mm

The factory covers an area of 11000 square meters, with fixed assets of 50 million yuan, working capital of 20 million yuan, and an annual output value of approximately 120 million yuan

Holding D1 and D2 pressure vessel design licenses, A2 manufacturing licenses, and pressure pipeline manufacturing licenses

Sincerity and trustworthiness, precision and excellence, seeking truth and pragmatism, and harmonious development

One word, nine tripods, brave in innovation, honest and pragmatic, harmonious and win-win situation

One word, nine tripods, brave in innovation, honest and pragmatic, harmonious and win-win situation

The TQ series static multifunctional extraction tank is a commonly used equipment in industries such as pharmaceuticals and food. Its core features focus on strong process adaptability, reliable safety performance, and compliance with industry standards. At the same time, it also has significant advantages in structural design and operational convenience, as follows:

The mixed ion exchanger (referred to as "mixed bed") is a core equipment for the preparation of pure/ultrapure water in the power industry. With its core advantages of deep desalination (simultaneous removal of cations and anions in water), pure effluent water quality (conductivity ≤ 0.1 μ S/cm, SiO ? ≤ 20 μ g/L), and stable operation, it is suitable for the strict requirements of the power indust

Spiral plate heat exchangers enhance heat transfer through structural optimization, improve turbulence level through channel design, reduce heat transfer thermal resistance, and achieve efficient heat transfer with small temperature differences (usually below 5 ℃). The core logic is the heat transfer coefficient and heat transfer area. The specific implementation method is as follows:

The core application of cover filters is high-precision solid-liquid separation, which is widely used in industries that require high water purity or material clarity due to its filtration characteristics that can form a "cover film".

The selection of ion exchange columns should be comprehensively judged based on processing requirements, medium characteristics, and operating conditions to ensure separation efficiency and system stability.

The core advantage of WFE thin film evaporator (i.e. scraper thin film evaporator) is its suitability for evaporating, concentrating, desolving, and purifying materials that are thermally sensitive, highly viscous, prone to crystallization or scaling. With its short residence time and low-temperature evaporation characteristics, it is widely used in industries such as pharmaceuticals, chemicals, f

WeChat number:WEIXINHAOMA

WeChat number:WEIXINHAOMA

Add WeChat friends to learn more about the product.